Durability and Slip Resistance in Safety Footwear

Essential Durability Features in Safety Footwear

Impact of Materials on Safety Shoes

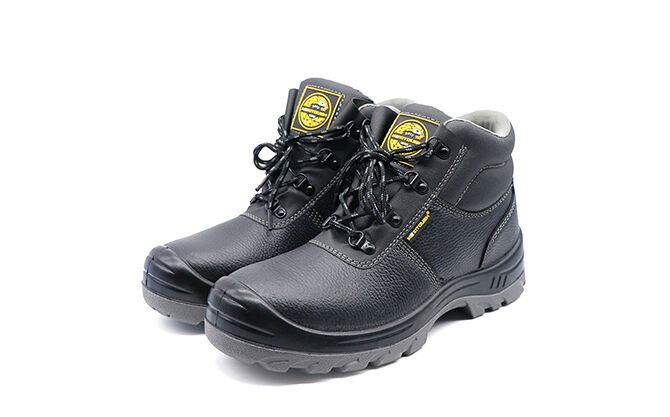

The choice of construction materials plays a pivotal role in the durability of safety footwear. Among the commonly used materials, leather, synthetic fabrics, and rubber stand out for their unique advantages in prolonging the lifespan of these shoes. Studies have shown that leather, a popular choice for its durability, offers high resistance to wear and tear, making it a preferred option for many safety shoes manufacturers. Synthetic fabrics, while lighter, provide superior abrasion resistance, contributing to the shoe's longevity in harsh environments. Additionally, rubber, often used for soles, offers excellent traction and resistance to extreme temperatures, which enhances the durability against various environmental factors.

Advanced materials have further revolutionized the durability of safety footwear. Innovations such as Kevlar and composite materials provide enhanced wear resistance, crucial in high-wear settings. Industry durability tests have consistently demonstrated that footwear incorporating these materials withstand prolonged exposure to challenging environments far better than traditional boots. Such materials not only enhance the longevity of safety shoes but also ensure they remain effective in protecting wearers from occupational hazards. This commitment to using quality materials underpins the reputation of leading safety shoes companies.

Reinforced Design Elements for Workplace Demands

Safety footwear's reinforced design features are instrumental in addressing workplace hazards effectively. Key elements such as steel toes, reinforced heels, and protective midsoles are essential in fortifying the footwear against potential impacts and abrasive surfaces. Steel toe work boots for men are particularly valued for their ability to shield the feet from heavy objects and accidental falls, offering robust protection in diverse industrial settings.

Injury statistics underscore the importance of reinforced safety footwear in reducing workplace accidents. Experts from reputable safety organizations often highlight that shoes equipped with protective design elements significantly decrease the likelihood of foot injuries. For instance, studies from workplace safety agencies reveal that incorporating features like reinforced midsoles can dramatically cut down puncture risks, ensuring better safety for workers. By adopting such reinforced designs, safety shoes companies are contributing to safer workplace environments while enhancing the overall effectiveness of their products in combating occupational hazards.

Science Behind Slip-Resistant Safety Shoes

SRC Rating and HSL GRIP Testing Explained

Understanding the SRC rating is essential for comprehending the effectiveness of slip-resistant shoes in safety footwear. The SRC rating evaluates footwear based on its ability to maintain grip on different surfaces; it combines the results from the SRA and SRB tests. The SRA test involves a ceramic tile floor with a soap solution, while the SRB test is conducted on a steel floor coated with glycerol. If a shoe passes both tests, it earns the SRC rating, indicating the highest level of slip resistance. This testing ensures that safety shoes meet specific criteria to combat workplace slip hazards.

HSL GRIP testing provides another layer of insight into slip-resistant footwear. The Health and Safety Laboratory's GRIP rating focuses on the human gait cycle to assess grip under real walking conditions. Boots are tested while worn, and the testing process accounts for how individuals walk, providing a more accurate representation of real-world use. This makes HSL GRIP an important consideration for many safety footwear brands looking to ensure their products offer optimal slip resistance in various working environments.

Tread Patterns for Optimal Surface Adhesion

Tread patterns play a crucial role in enhancing the slip-resistance of safety footwear. These patterns are specifically designed to optimize surface adhesion and accommodate different work environments. For instance, hexagonal treads are known for their ability to disperse water efficiently, which is vital in slippery conditions. Similarly, angled heel designs can enhance braking and slip prevention by increasing contact with the ground. By carefully structuring treads, manufacturers optimize footwear for specific terrains, maximizing their effectiveness.

User feedback and case studies provide substantial evidence on the effectiveness of various tread designs. For example, employees working in wet environments reported significant improvements in stability and safety with custom-designed treads. Such feedback helps refine safety shoes to address specific needs better, ensuring they perform well across various surfaces. This highlights the importance of integrating appropriate tread patterns to craft shoes that balance functionality and safety.

Material Comparison: Rubber vs. Polyurethane Outsoles

Performance in Oil and Water Exposure

When comparing rubber and polyurethane outsoles, it's essential to consider their performance in oily and water-exposed environments. Rubber outsoles are known for their excellent slip resistance, making them an ideal choice for wet or oily surfaces. Rubber's flexibility also allows it to maintain grip in varying conditions; however, it can suffer from quicker wear and tear over time. On the other hand, polyurethane outsoles demonstrate superior durability and resistance to abrasion and corrosion from chemicals, which is why they often outperform rubber in long-term scenarios. Studies indicate that polyurethane maintains a stable performance even when exposed to oil and water, making it a reliable choice for those seeking longevity and slip resistance. Each material has its advantages: rubber offers immediate grip, while polyurethane excels in durability over prolonged exposure.

Cold Weather Flexibility and Heat Resistance

The adaptability of rubber and polyurethane varies significantly with temperature changes. Rubber outsoles provide excellent heat resistance, making them suitable for high-temperature environments without losing flexibility. However, in cold weather conditions, rubber can become less pliable, which can affect traction. Polyurethane outsoles, in contrast, offer consistent flexibility even in low temperatures, maintaining surface contact and ensuring grip. Moreover, anecdotal evidence from workers in extreme conditions shows that polyurethane outsoles retain a soft texture, aiding in shock absorption and reducing fatigue during prolonged wear. Workers in cold environments often prefer polyurethane for its reliable performance in maintaining grip and comfort, while rubber is favored for its resistance to heat. Both materials have their applications, but polyurethane's adaptability to cold weather gives it a slight edge in terms of versatility.

Safety Standards and Manufacturer Compliance

EN ISO 20345:2022 Updates for Footwear Safety

Recent updates to the EN ISO 20345:2022 standards have introduced significant enhancements in safety footwear design and performance. This latest version focuses more on ensuring footwear meets rigorous requirements in slip resistance, energy absorption, and protection against perforation. Such updates are crucial as they reflect changing workplace dynamics and safety needs, ensuring that safety shoes can withstand modern industrial challenges. Compliance with these standards is meticulously monitored, with regular testing and certification benchmarks that leading safety shoe manufacturers must meet. Companies that achieve this compliance demonstrate their commitment to providing high-quality and reliable safety footwear.

Selecting Certified Waterproof Safety Shoes

Selecting waterproof safety shoes that meet specific certifications is critical for ensuring protection in wet environments. Waterproof ratings, indicating resistance to water penetration and absorption, are essential criteria when evaluating these shoes. Certified footwear provides a barrier against inherent hazards in wet workplaces, such as slipping or prolonged exposure to moisture. Safety professionals frequently stress the importance of choosing certified waterproof footwear to safeguard workers effectively. Testimonials from experts in industries like construction and logistics underscore that such shoes significantly reduce the risk of slip-related injuries and contribute to overall workplace safety.

EN

EN

AR

AR BG

BG HR

HR CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL RO

RO RU

RU ES

ES SV

SV TL

TL ID

ID SR

SR VI

VI HU

HU MT

MT TH

TH TR

TR AF

AF MS

MS GA

GA BN

BN NE

NE